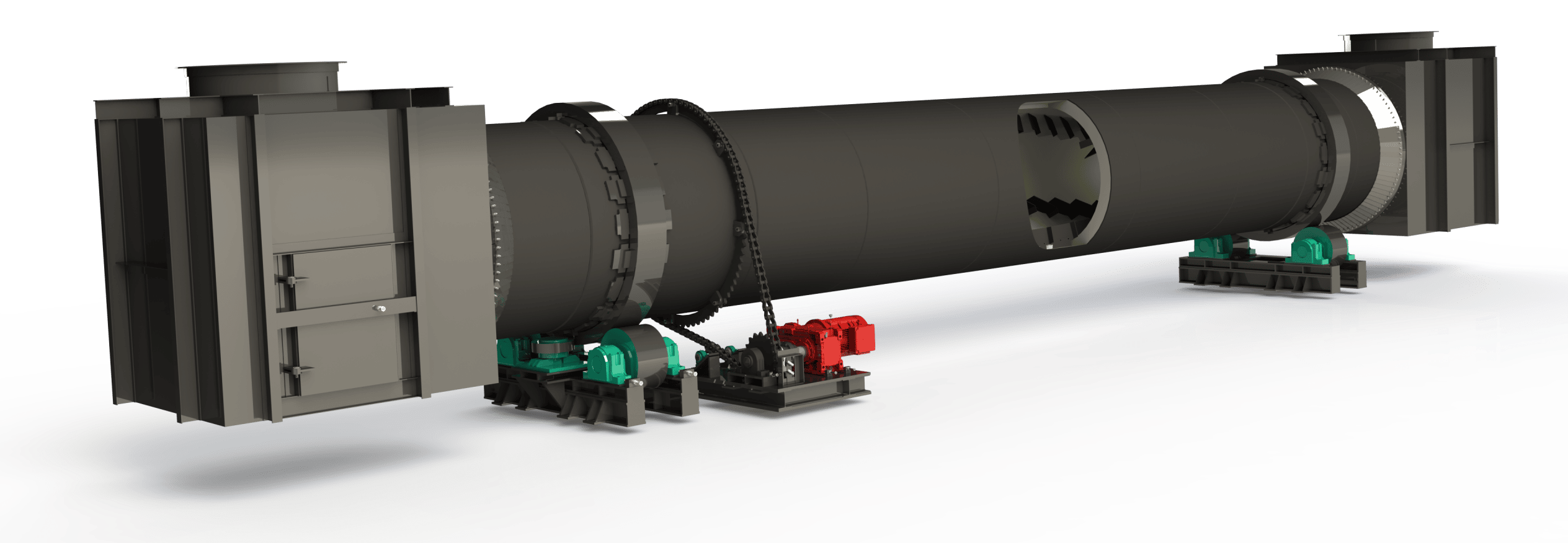

1. Discharge and Inlet Hoods

Hoods of all shapes and sizes to fit your kiln or dryer. Our hoods can fit any burners, instrumentation, sight port, or other accessory to monitor and control your process. Finch provides hoods in carbon steel, stainless, or other materials to meet your specific needs.

2. Tire mounting systems

Finch designs and manufactures various tire mounting systems for any rotary unit. Shown is a floating pad system that is designed to allow for thermal expansion while securing your tire or riding ring in place. This recommended design allows for the longest lifespan for your tires due to the allowance to shim.

3. Tires (Riding Rings)

The highest quality forged steel tires are fully machined to precise specifications and designed to fit your application.

4. Spur Gears, Sprockets, and Chains

Any size spur gear, helical gear, or chains and sprockets for your equipment. Our forged steel gears and high-quality sprockets are hardened for maximum lifespan and designed to meet and exceed your needs.

(Chain-driven sprocket shown in the diagram)

5. Complete Drums and Shell Sections

Complete drums and replacement shell sections rolled to precise standards to ensure complete concentricity with your tires and existing shell sections.

6. Drum Internals and Refractory

Flighting is designed for your specific material handling needs and throughput goals. Finch also provides refractory and other internal components such as chain curtains for dust control and to prevent material buildup.

7. Seal Systems

Custom seal systems for all sizes of rotary equipment. We supply seal systems such as leaf seal, Kevlar, graphite, and brush systems to improve the efficiency of your process by helping to reduce gas usage and to keep dust mitigated.

8. Trunnion Base Frame

Engineered base frames are designed to fit your equipment. Whether a new build or a modernization/replacement of an existing base frame, we field measure and design to your specifications to ensure a 100% fit.

9. Drive Base Frames

Finch engineers drive base frames for your existing drive system or new equipment installation. Finch’s drive base frames typically use a common plate design for simpler adjustability, especially on gear-driven units.

10. Drive Motors

Finch can provide replacements for any existing motor and can work with you to ensure you are getting the right size for your application for optimal efficiency.

11. Gear Reducers

We work with our customers to ensure provided motor and gearbox combination will be a 100% fit for your final drive needs while also meeting all torque and power requirements. Finch supplies all types and sizes of reducers to meet your power, torque, and operating speed needs.

12. Auto Lubrication Systems

Auto lubrication systems reduce maintenance time and guarantees regular lubrication of all your components. Finch partners with industry experts to ensure the best lubricant for your application. Set your lubrication interval and volume and let the system minimize down time, increase the lifespan of your drive, and reduce your PM planning schedule.

13. Pinions and Drive Sprockets

Forged steel pinions, and high-quality sprockets to meet your requirements to mate with your existing drum gear or drive chain. We can reverse engineer sprockets and pinions if you do not have a drawing.

14. Bearings

Finch supplies high-quality brand-name bearings to meet the needs of our customers. When faced with availability issues and long lead times we use our expansive network of partners and vendors to find suitable alternatives. We also machine custom bronze bushings for larger kilns and can pour and machine babbitt bearings.

15. Trunnions

Manufactured from the highest quality forged steel and heat treated to our custom specifications based on years of knowledge and experience. Our trunnions are built to last. Finch offers refurbishment services. The roller face is machined true, the shaft repaired or replaced, and the surface re-heat treated to ensure the same Finch quality while saving you money.

16. Thrust Rollers

Thrust rollers made of the highest quality steel and bearings designed to fit your application. We can reverse engineer and field measure your existing and/or work with you for a new application. Whether it’s a straight or angled face, we make them all.