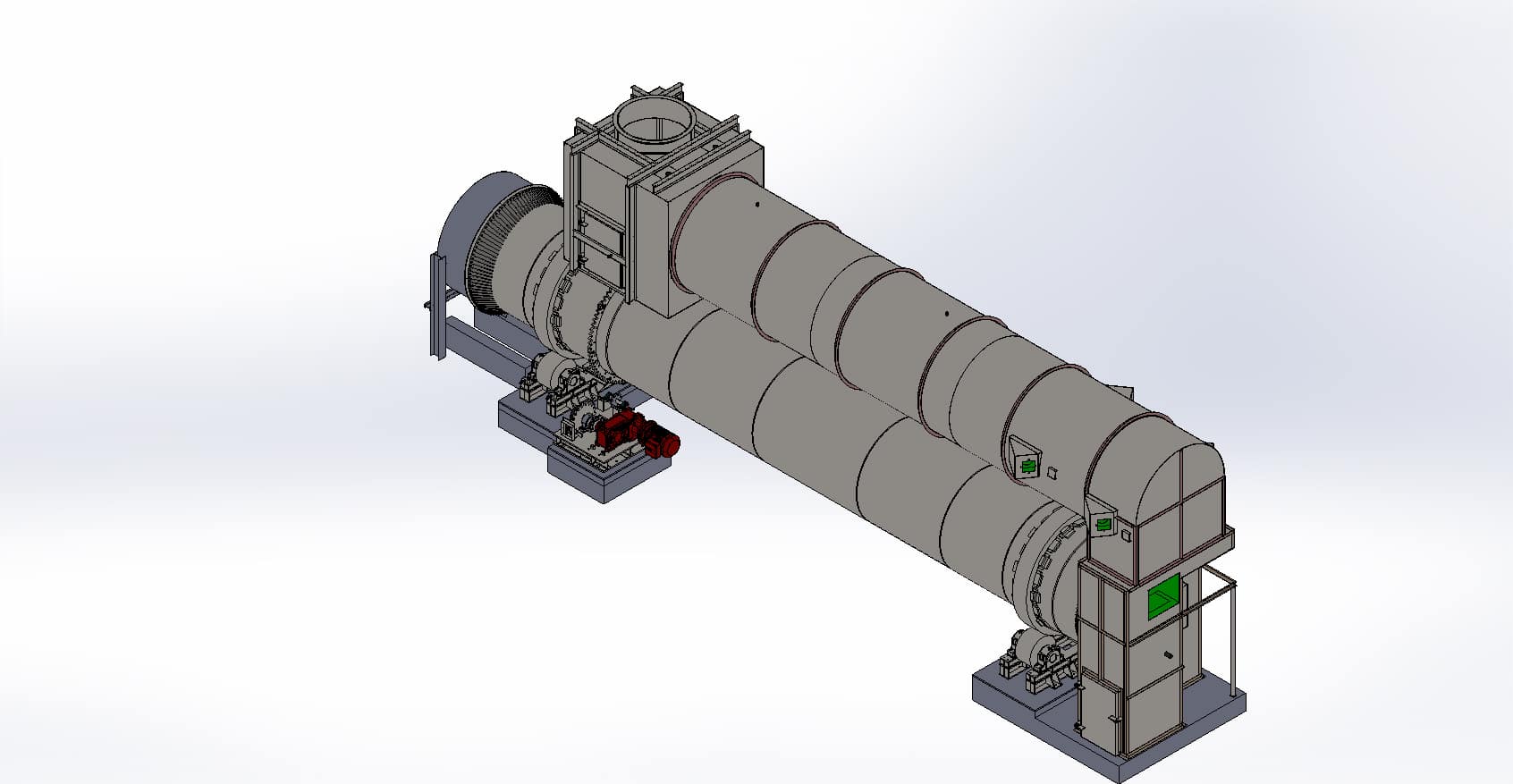

Finch has an exemplary team of engineering professionals with expertise in field work and design. Whether the need is for replacement parts or complete rotary systems, Finch has engineered and designed solutions for simple and complex projects. We support all brands of equipment.

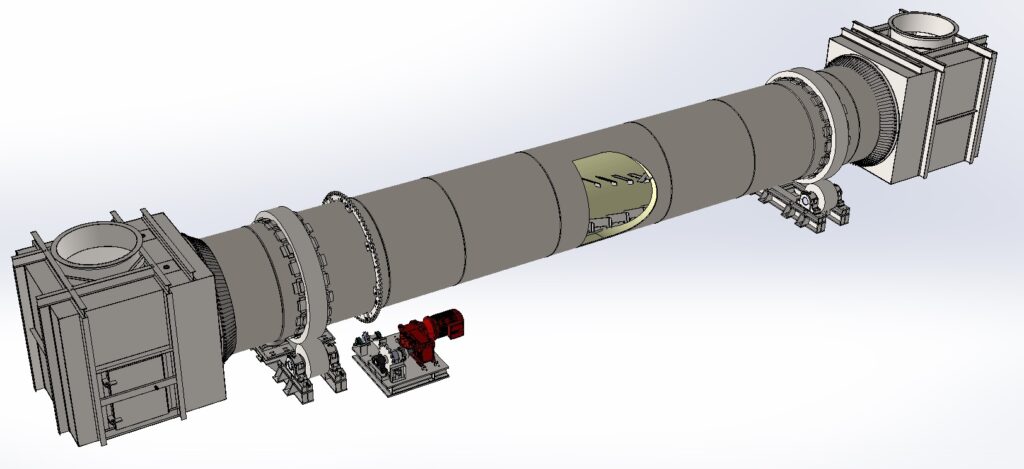

Rotary Dryer

Finch closely monitors all action steps in each project and understands that projects have critical path items that must be actively managed to keep the project on time! Our team, from sales to engineering to the assigned project manager, works with our customers in a customer-centric manner. We are available 24/7 and will send weekly updates with pictures or communicate as requested by the customer to ensure open and effective communication with no surprises.

Aluminum Recycling Rotary Kiln and Afterburner

Engineering Startup Support

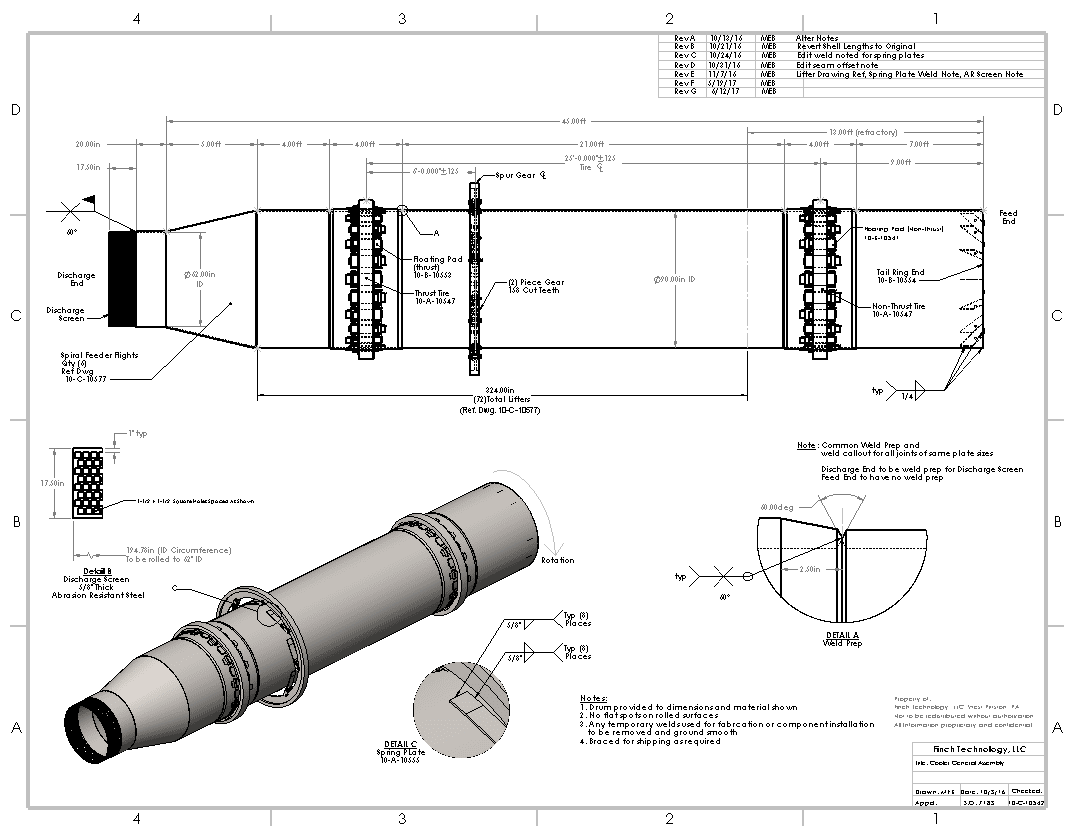

Rotary Cooler Engineering Print

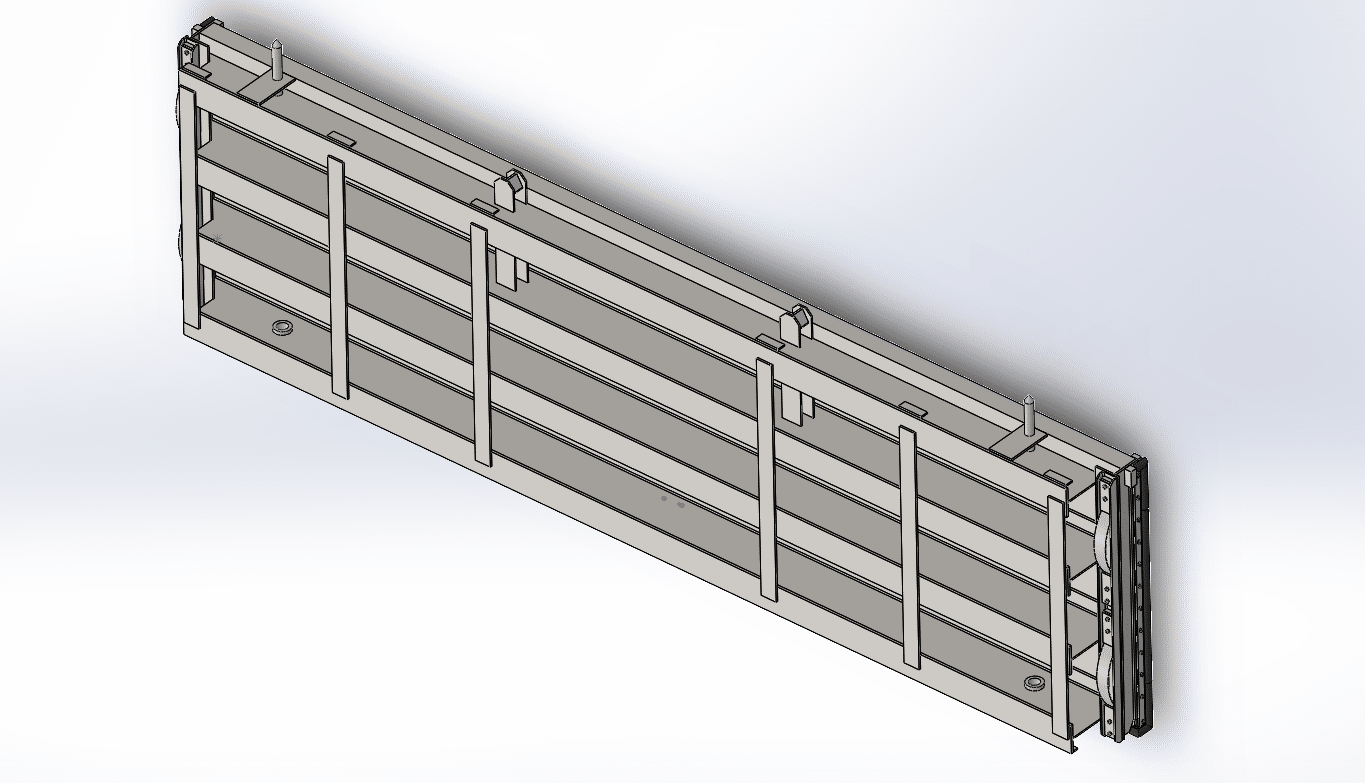

Stop Log Model

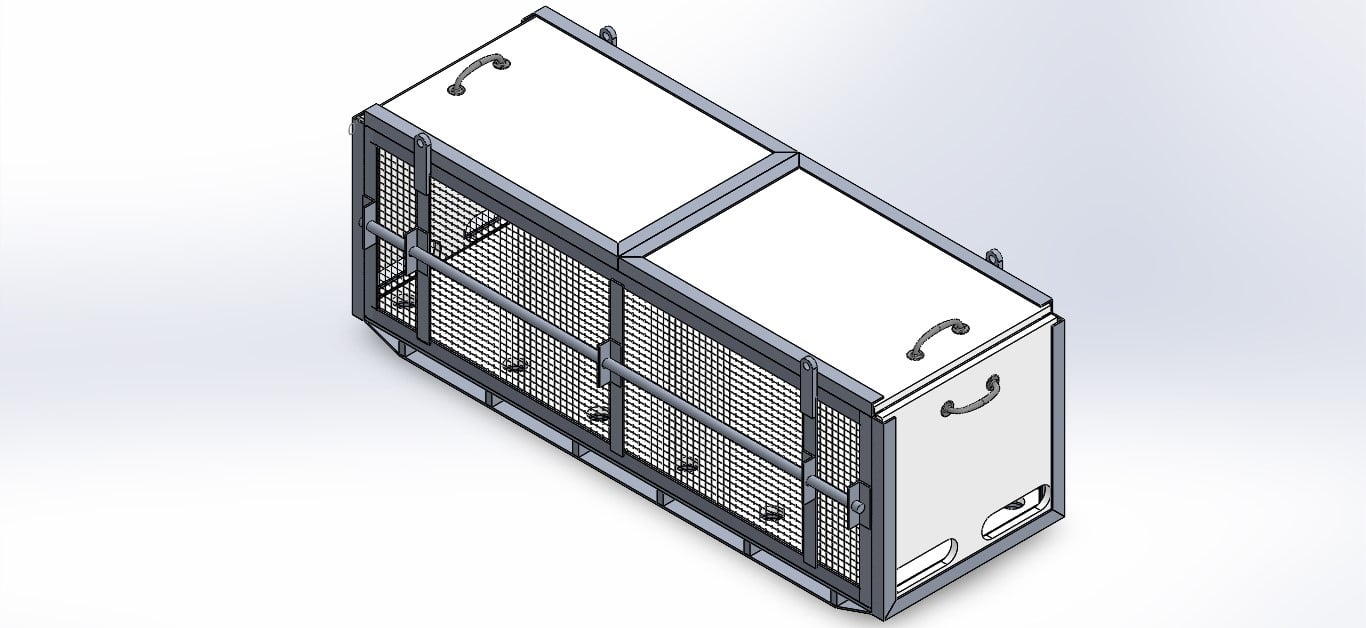

Solid Model Wildlife Container

Field Services for Rotary Kilns & Dryers

Finch provides extensive engineering support and project management in the field. Finch’s rapid response services minimize outage downtime, ranging from simple grind and alignment to complex repairs and installations. We know that there is often a single point of failure in rotary processing equipment. Hence, our customers rely on Finch because of our reliability, expertise, quality products, and ability to provide real solutions.

Checking Tire Gap on a Rotary Dryer

Inspecting Used Equipment

Measuring to Design a Replacement Drum

On several occasions, we have had an Engineer en route the same day our customers called with a problem. Kiln and Dryer Analysis and Corrective Action Visits are becoming familiar to our customers since we can provide critical information about their systems to provide immediate solutions, enhance throughput system reliability, or develop longer-term budgetary proposals. A quarterly inspection program has improved our customer’s operational efficiency. We have increased our field service capabilities to service many industries and worked on conveyor installations and modernizations, bucket elevators, and screw auger replacements.

We have increased our field service capabilities to service many different industries and have worked on conveyor installations and modernizations, bucket elevators and screw auger replacement.

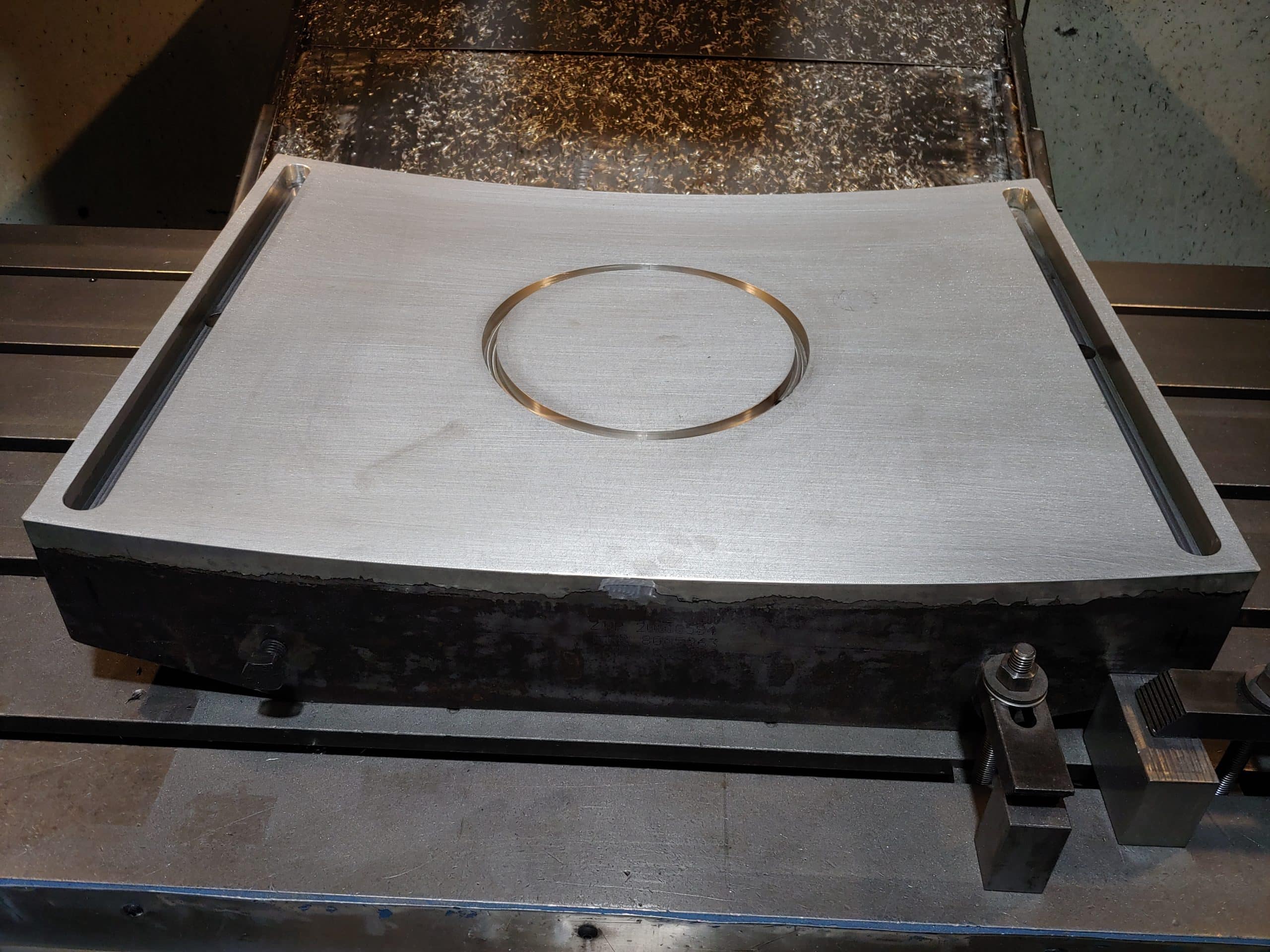

Drive Shaft Preparation

Since downtime is costly, we believe in preventive and predictive maintenance and routine inspections to ensure the system runs as efficiently as possible.

A few of the Field Services we offer are:

- Rotary Kiln & Dryer Tire & Trunnion Resurfacing

- Rotary Kiln & Dryer Alignment

- Unit Inspections, Analysis & Corrective Action Reviews (Running & Shutdown)

- Predictive Maintenance Systems

- Rotary Kiln and Dryer Tire & Pad Installation or Repairs

- Trunnion, Thrust Roller & Base Frame Installation

- Trunnion & Thrust Roller Bearing Replacement

- Spur & Pinion Gear Installation

- Project Management

- Site Management & Supervision of In-House Installations

Rotary Kiln Shell Section Installation

Refurbishment of Rotary Kiln & Dryer Parts

Finch can fully restore and refurbish expensive parts that are no longer available. Whether refurbishing castings, shafts, or trunnions, Finch has the in-house capacity to give new life to your part and save you time and money. We have been refurbishing rotary processing equipment for years.

Examples of parts or equipment we have refurbished:

- Site Management & Supervision of In-House Installations

- Trunnion Assemblies – Housings, Shafts &Trunnions Heads

- Thrust Rollers

- Trunnion Bearing Housings & Bushings

- Drive Systems

- Gears

- Rock Crushers

- Augers

- Conveyor Systems

- Underwater Screening Shafts & Equipment

- Construction & Heavy Equipment Repair

Relined and Machined Babbitt Bearing

Resources