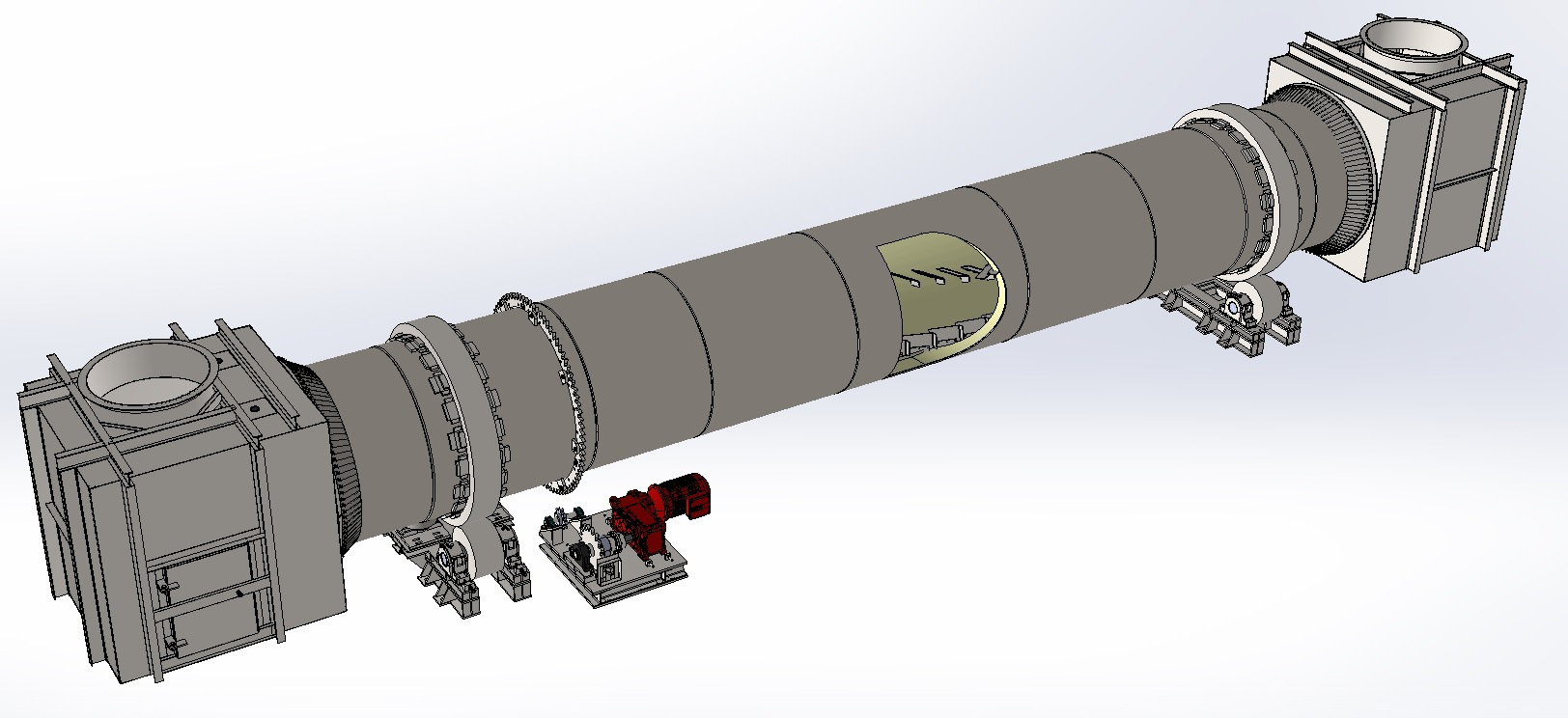

Replacement/ Upgrade Dryers and Kiln Systems

Properly maintained rotary kiln and dryer units can last for many years, but like anything else it will need to be repaired or replaced.

Over time, rotary shells wear out. This can lead to the shell wearing thin and even cracking, leading to a catastrophic failure! To get ahead of any failures, Finch offers ultrasonic thickness testing to map your shell and show weak points before they fail, keeping you up and running. This service can also help you plan for your upcoming repair outages.

Whether you determine you need a simple shell section replacement or a complete unit, Finch can provide all components and installation/repair services needed to keep you up and running. Properly planning ahead for these large repairs/replacements, which can be timely to manufacture, is key to keeping your throughput at peak and your equipment at its highest efficiency.

During the proposal process for a system replacement, Finch’s engineering team can also help improve your equipment for more efficient and reliable operation by helping to analyze how to increase throughput, verifying your refractory lining, adding seal systems, modifying any lifters for better material flow, and upgrading base frames, rollers, and feed and discharge hoods.

If you feel you need a system upgrade call Finch today to plan a meeting to review your company’s needs!