Finch worked closely with a customer to simplify and standardize the kiln tire assembly that can be quickly mounted on the drum to reduce downtime. Also, Finch created a remanufacturing process for these assemblies. This customer recently asked Finch to do the same design process for the other tire assemblies in the plant.

Project Overview

Project Specifications

- The Finch engineering team worked closely with customer to simplify the design to reduce cost and manufacturing time.

- Customer approved the drawing and a test tire assembly was fabricated. After testing, this design was approved and a stock number given.

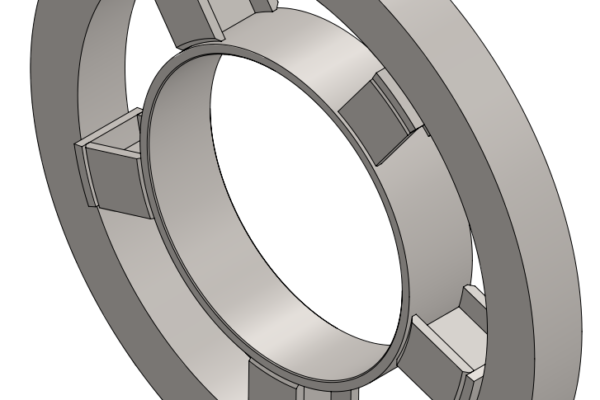

- Standardized kiln tire assembly consists of:

- Outer tire with a 6” face

- 1045 forged steel with 220-260 BHN

- 250 RMS finish

- Inner Mounting Hub:

- 1045 forged steel with 220-260 BHN

- Machined for slip fit onto shell

- Tire mounting blocks.

- Assembly is machined and fabricated with full welds.

- This customer ships used tires back to Finch to determine if the inner hub or other parts can be reused. Finch stores the reusable parts and uses them on the next order which reduces cost.